The Autobar RFID System is considered to be one of the most robust and  agile solutions for the industries where tracking of an item is done. And it is safe to say that RFID is making barcode look old school (despite RFID being an older technology).

agile solutions for the industries where tracking of an item is done. And it is safe to say that RFID is making barcode look old school (despite RFID being an older technology).

Autobar provides Supply chain operations, for every industry, play an important role in determining business success. If you are planning strategies for the better supply chain in your industry, your meeting will include the following agendas:

- To determine the inventory in real-time

- To ensure all items are logged and accounted for.

- To know for sure where an item is within the warehouse.

- To store every data accurately.

To improve the inventory system, ensuring no item is wasted:

These are simply an overview of the vast ideas that are discussed above.

When you are using paper for all these activities: As soon as an item arrives, you note down several details in a register and log the entry. You manually register the shelve number, aisle number, section, etc. in your diary so that you can find the item when needed. When an item goes out of the store, you clear the entries in the file and mark it to the destination it is going and hand over the sheet to them.

When you are using Microsoft Excel for these activities: When an item arrives, you enter all the details in the MS Excel sheet and save it. Then you assign a place in the warehouse for the item and log the entries. Whenever the product is shifted, you update the entry in your sheet so that the item is not lost inside the warehouse. As soon as the item leaves, you share the excel sheet to the next person who will be taking care of the tracking of the item.

When you are using Microsoft Excel for these activities: When an item arrives, you enter all the details in the MS Excel sheet and save it. Then you assign a place in the warehouse for the item and log the entries. Whenever the product is shifted, you update the entry in your sheet so that the item is not lost inside the warehouse. As soon as the item leaves, you share the excel sheet to the next person who will be taking care of the tracking of the item.

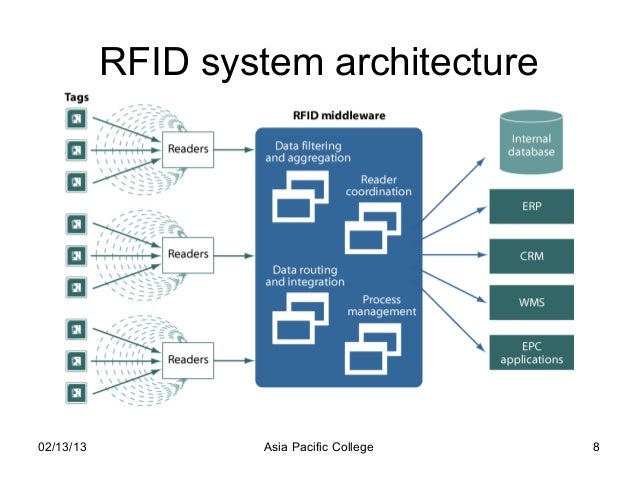

When you are using an RFID based supply chain solution, your process is something like this:

- The item is fitted with an electronic tag, called RFID tag, which will contain all the data that you need

- As soon as the item arrives, the RFID reader scans the tag and logs the entry to the database

- RFID readers can read a tag to a distance of several meters without a direct line of sight. Hence, your product will be always tracked within the warehouse

- Every entry and exit is logged electronically eliminating heaps of files

- The readers keep an eye on the item until it reaches the final station so that any issue, in future, can be easily traced back to the origin

When you are browsing for the best software solutions based on RFID technology to manage your supply chain management, you can always rely on the leaders in this field.

The RFID solution from Amity Software will give you the following benefits:

- Their system is transparent, i.e. that all the data should be accurately measured and recorded.

- Their system allows minimum dependency on human intervention. Humans make mistakes, machines don’t.

- Their system is highly accurate, i.e. the recording and tracking range of the RFID system is good enough to cover the entire floor (up to several meters)

- Their system stores all the information related to an item and makes sure that the inventory stored is properly accounted for.

- With the data from this system, you can even manage the shelf life of the items on display and replenish the stock on time.

Simply consult their team and learn how their proprietary software solution can help you manage your supply chain better and increase the profitability like hundreds of other businesses before you.